Railway

Railways, one of the most commonly used modes of transportation from the past to the present, have hosted different production techniques and material uses with the advancement of technology. Nowadays, geosynthetic materials used particularly during the establishment of railway tracks have not only accelerated the construction methodology but also ensured cost-effectiveness in material usage.

- To expedite the time-dependent settlements in soils with consolidation issues, you can use wick drains (strip drains)

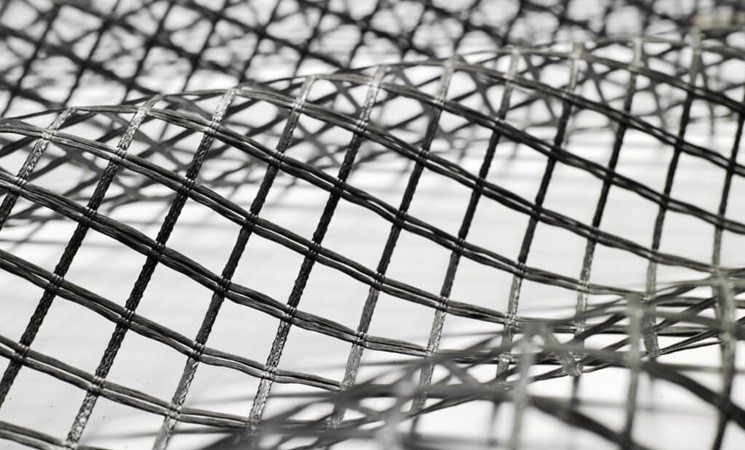

- In soils experiencing consolidation issues, soil reinforcement can be achieved in the subgrade layer using geogrids

- Geogrids are employed to increase the load-bearing capacity of ballast and sub-ballast materials (with a reduction in material volume)

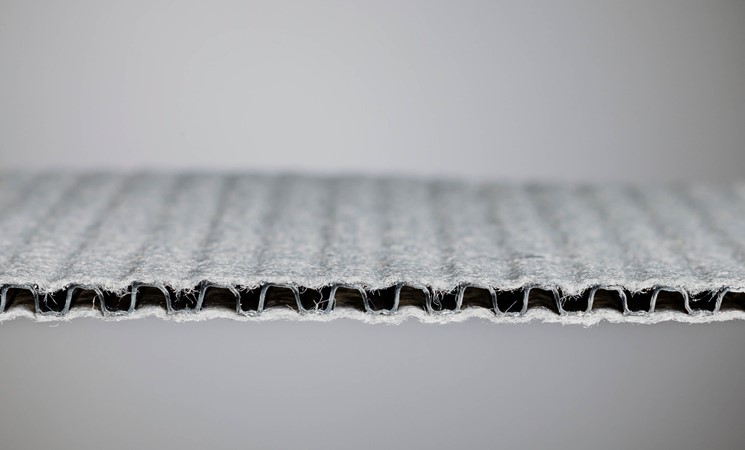

- Preventing the mixing of subgrade material with sub-ballast material can be achieved by using geotextile

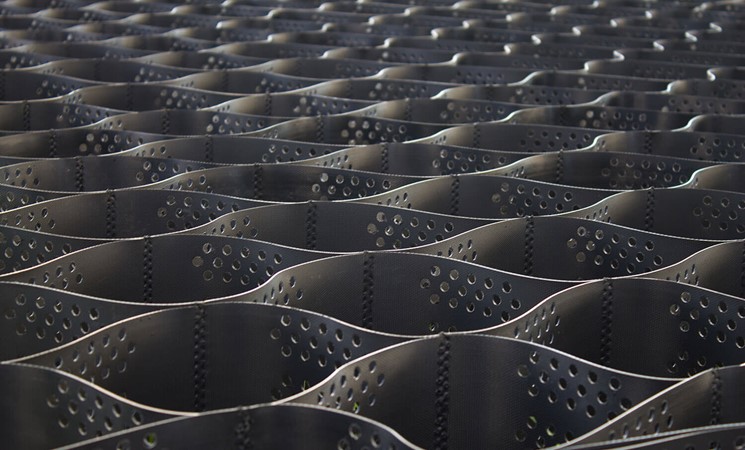

- Surface erosion on cut slopes can be prevented using geomats and cellular system materials

- Constructing platform embankments with geosynthetic-reinforced retaining walls is achievable

- In areas with capillary problems, accelerating the rapid removal of water from the platform can be achieved using drainage composites

- Forming the drainage line to be applied along the track with a geodrain (composite drainage system)

Geosynthetics in Railway

Geosynthetics are used in the construction and the maintenance time of the railway lines to provide the fast and economical solutions in railways.

Strengthening Ballast and Sub-ballast Layers with TechGrid Geogrids

Separation of subgrade and ballast layers and preservation of long-term material properties of ballast material with TechTex geotextiles."

Providing horizontal and vertical drainage solutions with Techdrain drainage composites

Creating cost-effective and efficient track drainage installations with Geodrain composite drainage system